After the successful launch of the project on 18 March 2016 at KTTC in Nairobi. The Devotra project implementation team made all arrangements for the procurement of all the hardware and software. And to build a complete mock-up of the Smart Classroom in the warehouse of Devotra.

At the same time preparations were made for the training of the Devotra Kenyan staff and the expert trainers from Denmark, UK and the Netherlands.

The final shipment date for the complete project was fixed at 01 June 2016. So a lot of activities had to run parallel and a full team of professionals were occupied to meet this deadline. Goods started to arrive at the Devotra warehouse as from 01/04 and step by step the full Smart Classroom was built to have an exact copy of the final composition at the 10 TTI’s in Kenya.

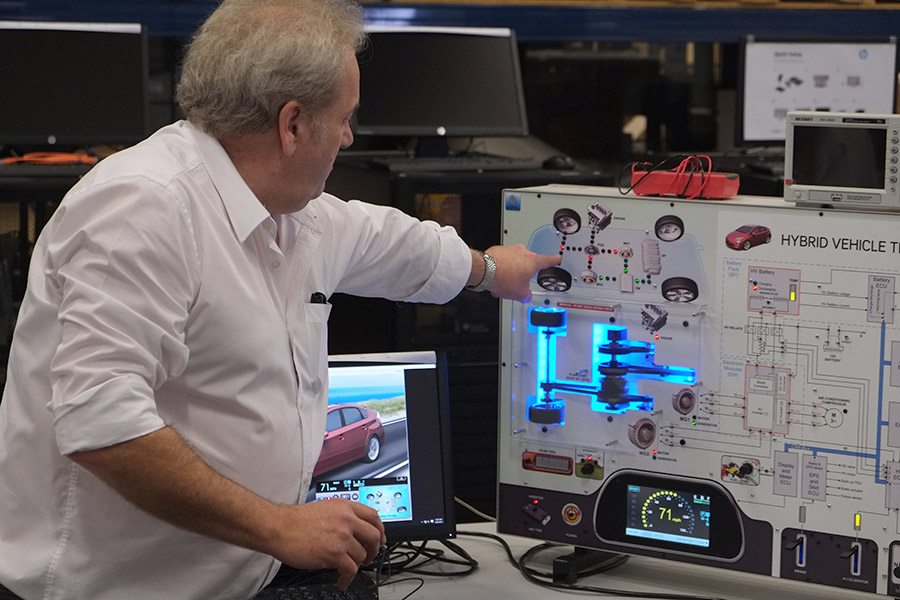

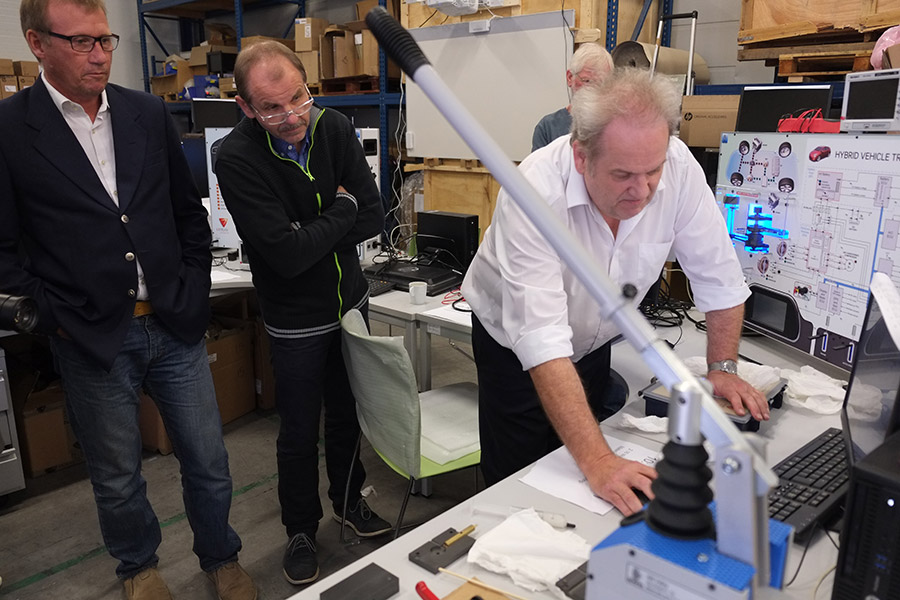

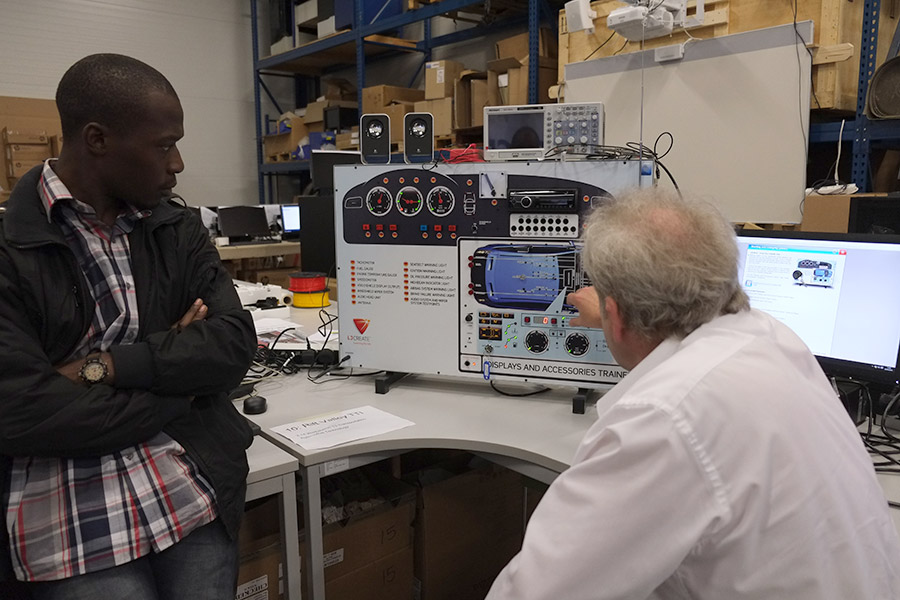

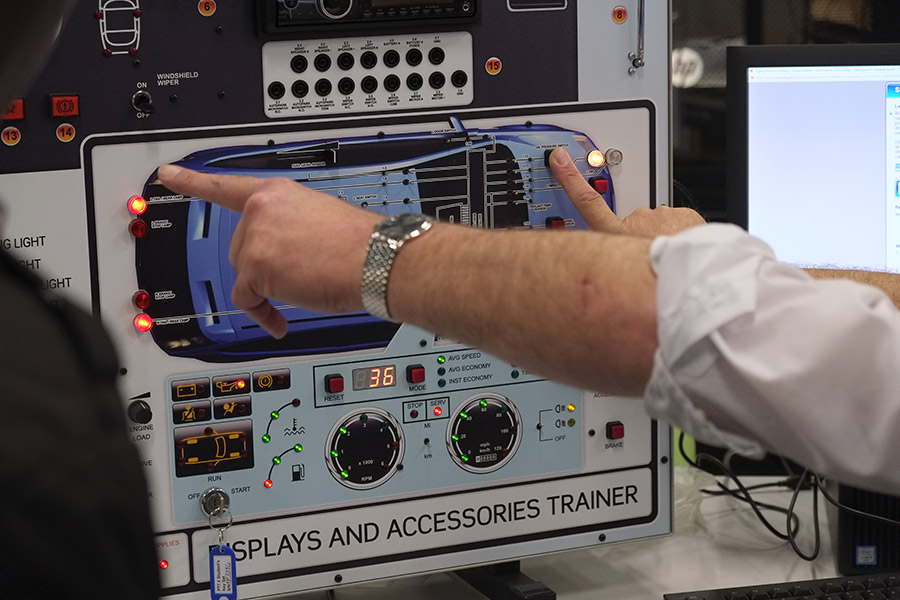

The idea was to have a fully operational Smart Classroom, so that all challenges could be identified during the preparation of this mock-up and to use the room for the training the Devotra international team of experts.

Training

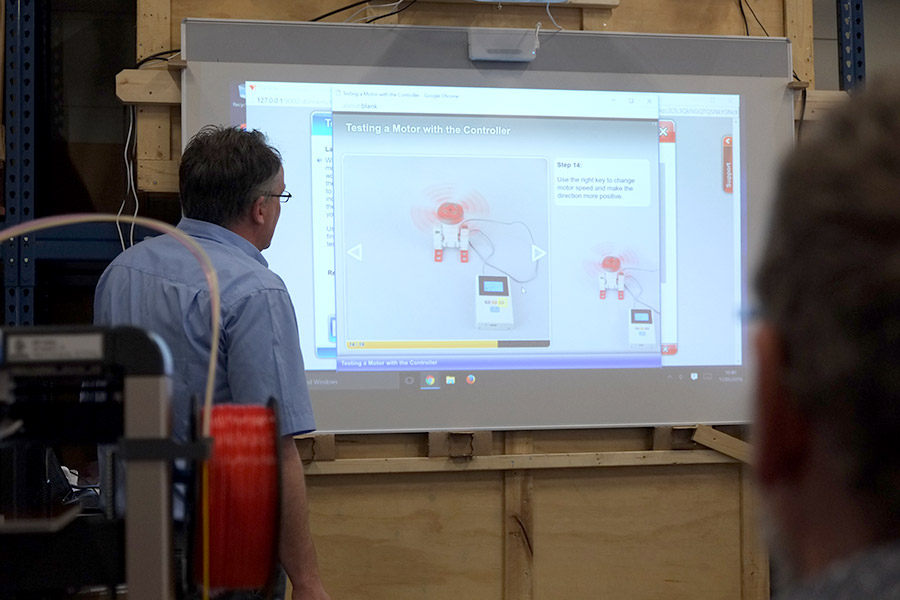

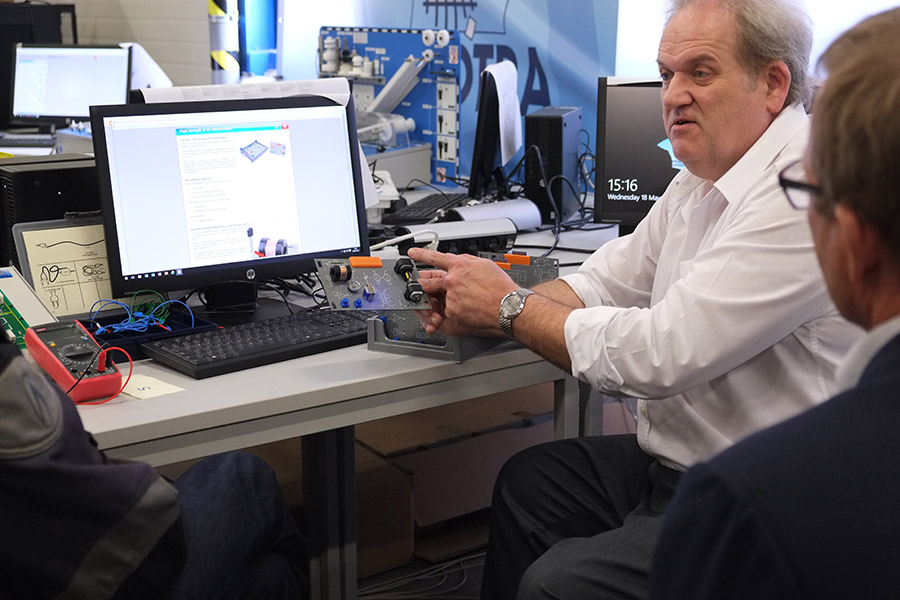

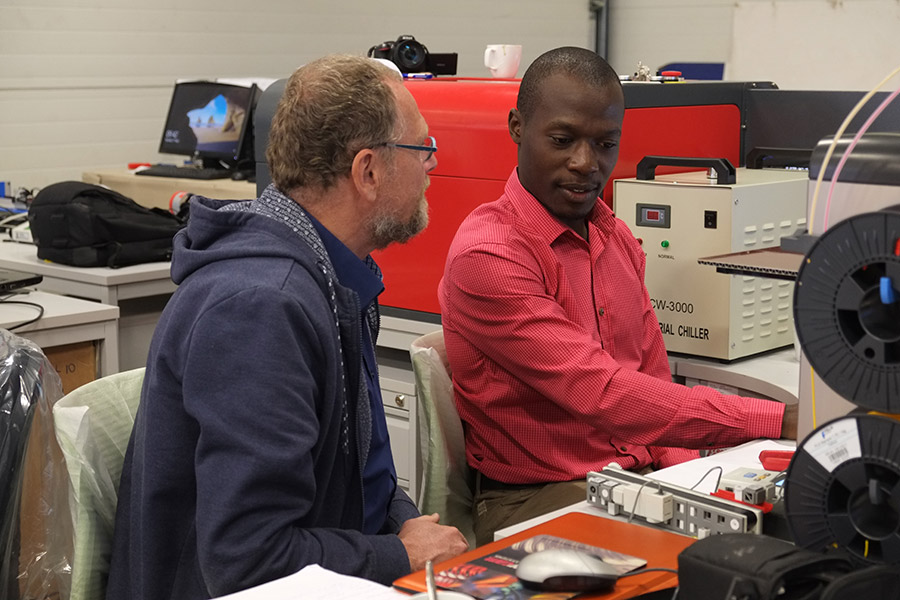

On 09/05 the mock-up was fully functional and the de Devotra Kenya and UK experts started with the basic training. Later that week the experts from Netherlands and Denmark joined and a full team of 6 Devotra experts received ongoing training till 20 May. Product experts of the different manufacturers came to Devotra in Tholen to conduct a thorough training program on the equipment supplied and in particular all the different features of the Digital Library, the heart of the Smart Classroom.

Testing of hardware and installation of software

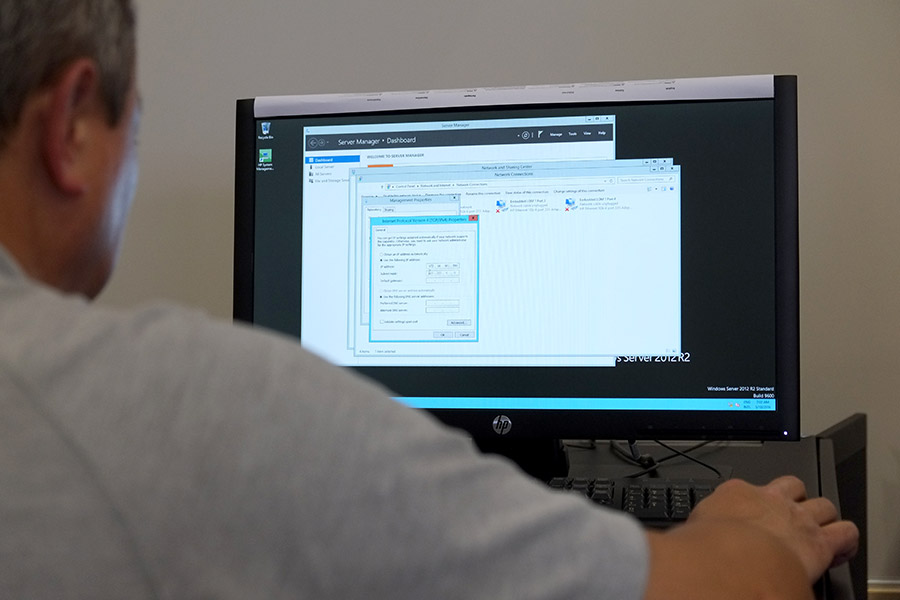

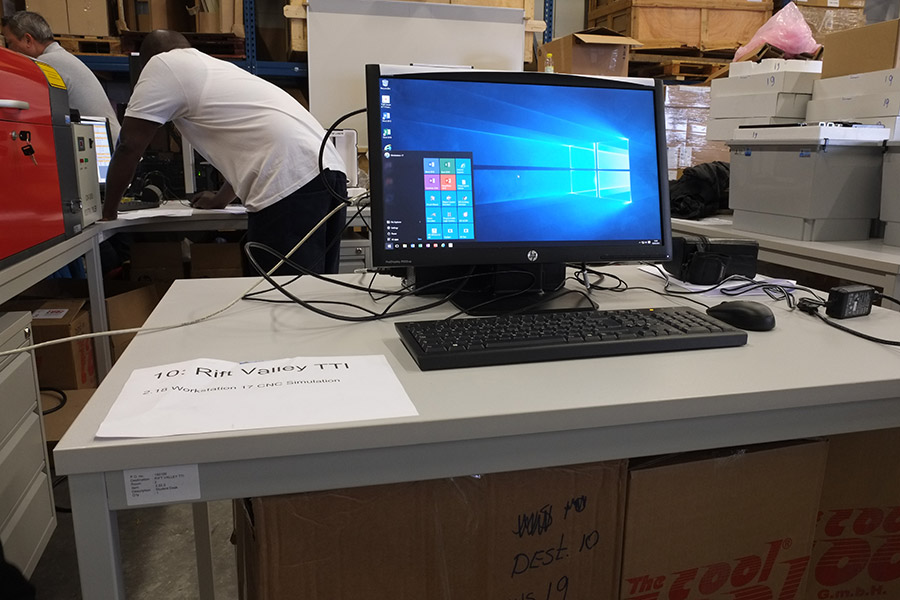

Devotra hired the expert services of Lantack BV, their regular IT services provider, for the testing and installation of all the hardware and specific software. And to ensure that the 10 servers communicated properly with the 200 workstations. Devotra’s in-house It expert Mourad Tihani assisted Lantack and was responsible for the final selection of HP hardware and Microsoft related software packages.

Order-handling

Parallel to the training, Devotra’s logistics team consolidated all the goods of the 9 other TTI’s. All goods had to be checked on quality and quantity. After which these were labelled for easy identification on site. Once labelled all goods are grouped together and prepared for inspection by SGS a well-known worldwide recognized inspection agency.

Pre-shipment and KEBS PVoC Inspection by SGS

An inspector of SGS spent 2 days at the Devotra warehouse to do a thorough pre-shipment inspection in line with the Kenya Bureau of Standards (KEBS) Pre-Export Verification of Conformity (PVoC) program. This KEBS-PVoC program is now mandatory for all shipments to Kenya as from December 2015. And goods were inspected on: quality, quantity, CE conformity, manuals, labelling, origin, safety, etc.. No item was rejected and goods were released for final packing and shipment.

Final Packing & Consolidation

Once the goods were inspected and approved by SGS, the mock-up was dismanteld again and everything was consolidated per TTI for final packing, marking of cases and preparation of shipping documents. The final volume per TTI was exactly 1x 40ft container.

Loading

Loading of the 10x 40ft containers took place from 30/05 till 01/06, the full cargo was tightly secured by using so called air bags and all containers were sealed and locked. After release by customs the containers were transported to the terminal in Rotterdam.

Further planning and Implementation of the Project

The 10 containers effectively sailed on 04/06 and will arrive at Mombasa port around 17/07. It is anticipated that clearance and transport to final sites will be finalized around mid-August 2016. After which the equipment will be installed and the first training sessions will take place by the end of August at KTTC in Nairobi. In parallel another Devotra team will start the installation of equipment at the other 9 TTI’s. Devotra trainers will stay in Kenya till end of December 2016 to provide training and assistance wherever required. Furthermore there will be another 12 months technical assistance program to ensure sustainability of the project.

The Project partners